The Future of Manufacturing: Unleashing Potential with Rapid Prototyping Injection Moulding

Rapid prototyping injection moulding has emerged as a crucial game-changer in the manufacturing landscape. This innovative approach allows businesses to expedite their design and production processes, ultimately leading to enhanced efficiency and cost-effectiveness. In today’s competitive market, staying ahead requires adaptive strategies, and this technique is at the forefront of modern manufacturing.

What is Rapid Prototyping Injection Moulding?

Rapid prototyping injection moulding involves creating a physical part or prototype quickly using advanced software and manufacturing techniques. This process combines the principles of prototyping with the traditional injection moulding process to facilitate faster production timelines. Instead of taking months to develop and test a prototype, businesses can now achieve results in a matter of days.

Key Features of Rapid Prototyping Injection Moulding

- Speed: Rapid prototyping significantly reduces the time from concept to production.

- Cost-Effective: Lower initial investment in tooling and resources compared to traditional methods.

- Flexibility: Capable of accommodating design changes with minimal downtime.

- Quality: High accuracy and consistency in product quality.

- Material Variety: Compatibility with various materials, including plastics and metals.

How Does Rapid Prototyping Injection Moulding Work?

The process of rapid prototyping injection moulding can be broken down into several key stages:

- 3D Modelling: The first step involves creating detailed 3D models using CAD (Computer-Aided Design) software.

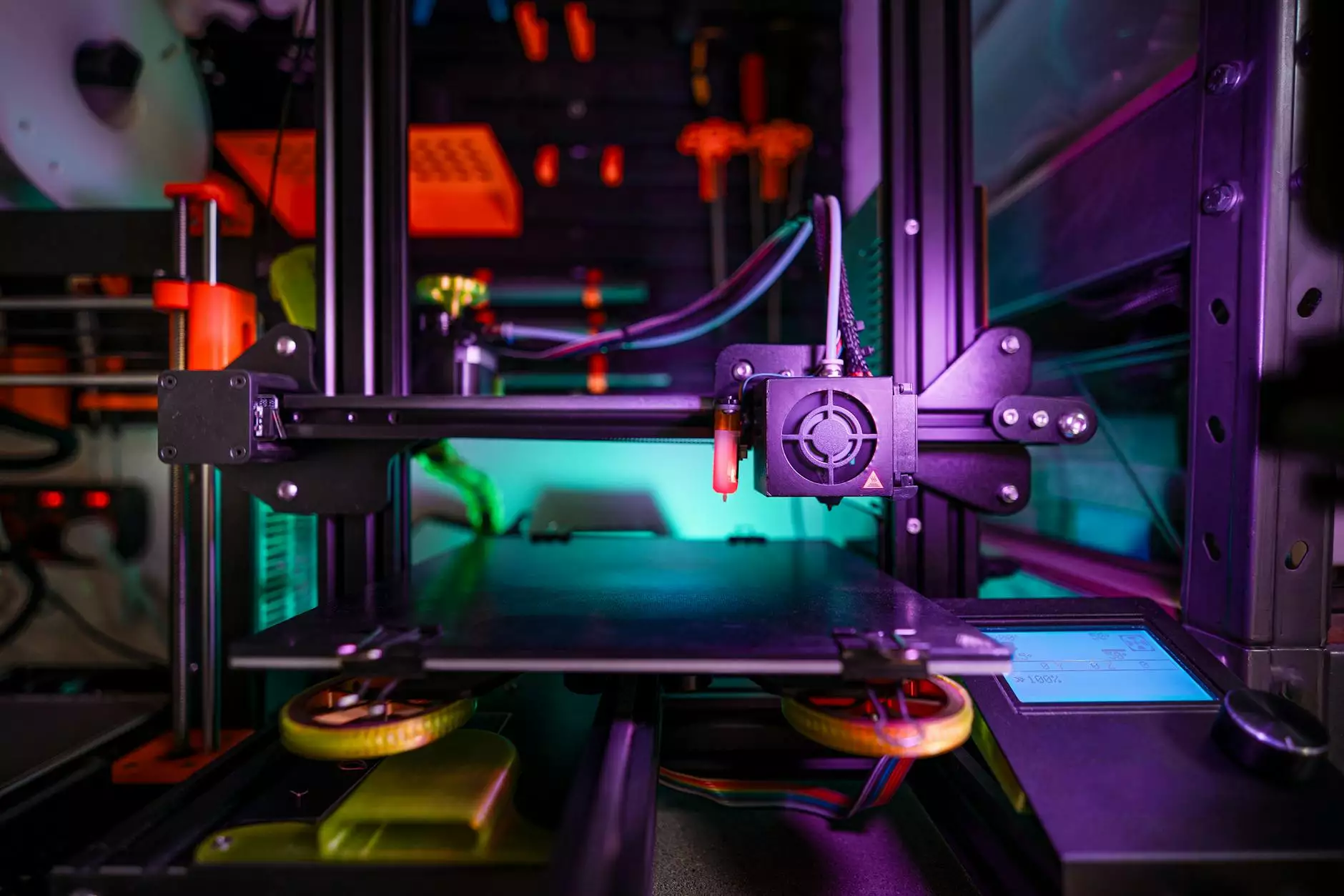

- Prototype Creation: Rapid prototypes are created through techniques such as 3D printing, which serve as a preliminary version of the final product.

- Mould Design: Once the prototype is validated, a mould is designed specifically for injection moulding.

- Injection Moulding: The final phase involves injecting molten material into the mould, producing high-quality parts.

The Role of Technology in Enhancing Rapid Prototyping Injection Moulding

In recent years, advancements in technology have significantly transformed the landscape of rapid prototyping injection moulding. These technological innovations include:

- Advanced CAD Software: Enhanced design capabilities to create complex geometries and features.

- 3D Printing: Facilitating quick prototype generation and testing.

- Smart Manufacturing: Incorporating IoT (Internet of Things) for real-time monitoring and adjustments during production.

- AI and Machine Learning: Utilizing data analysis to predict failures and design optimizations.

The Advantages of Adopting Rapid Prototyping Injection Moulding

Businesses that embrace rapid prototyping injection moulding can enjoy numerous advantages:

1. Accelerated Development Cycle

By significantly shortening the development timeframe, companies can bring products to market faster than ever before. This rapidity not only enhances customer satisfaction but also positions the business as a leader in innovation.

2. Reduced Costs

Traditional tooling methods often require significant financial investment. Rapid prototyping injection moulding reduces these costs by minimizing waste and optimizing the use of materials. Additionally, it allows for rapid iterations without the need for extensive retooling.

3. Enhanced Customization

In an era where personalization is key, rapid prototyping injection moulding allows for quick adjustments and customizations, catering to specific client needs while maintaining manufacturing efficiency.

4. Improved Market Readiness

With the ability to rapidly prototype and test designs, companies can gather feedback early in the development process, leading to products that better meet market demands.

Challenges in Rapid Prototyping Injection Moulding

While the benefits are substantial, it's vital to acknowledge the challenges associated with rapid prototyping injection moulding, which include:

- Initial Setup Costs: Although costs are lower than traditional methods, the initial investment for technology can be significant.

- Material Limitations: Not all materials are suitable for rapid prototyping, which can limit options.

- Skill Requirements: Specialized skills are needed to operate advanced machines and software.

Applications of Rapid Prototyping Injection Moulding in Various Industries

The versatility of rapid prototyping injection moulding means it can be applied across numerous industries, including:

1. Automotive Industry

The automotive sector benefits immensely from faster prototyping, which allows for the development of new parts, components, and even entire vehicles more quickly and efficiently than ever before.

2. Medical Devices

In the medical field, precision and reliability are paramount. Rapid prototyping enables the rapid development of custom devices that meet stringent regulatory standards.

3. Consumer Electronics

Electronics manufacturers utilize the speed of rapid prototyping injection moulding to iterate on designs, ensuring products stay relevant in a fast-paced market.

4. Aerospace

The aerospace industry demands high-precision parts that can be rapidly prototyped and tested, ensuring safety and compliance with industry standards.

Conclusion: Embracing the Future of Manufacturing

As businesses continue to navigate the complexities of modern manufacturing, the role of rapid prototyping injection moulding becomes increasingly vital. The potential for accelerated development, cost savings, and enhanced customization cannot be understated. Companies like DeepMould.net are paving the way for this revolutionary approach, enabling clients across various sectors to harness the power of innovative manufacturing processes.

In conclusion, the adoption of rapid prototyping injection moulding is not just a trend; it's a necessary evolution for businesses looking to thrive in a competitive landscape. By investing in this technology, companies can position themselves at the forefront of their industries, delivering high-quality products faster and more efficiently than ever before.

For more information about rapid prototyping injection moulding and how it can benefit your business, visit DeepMould.net.